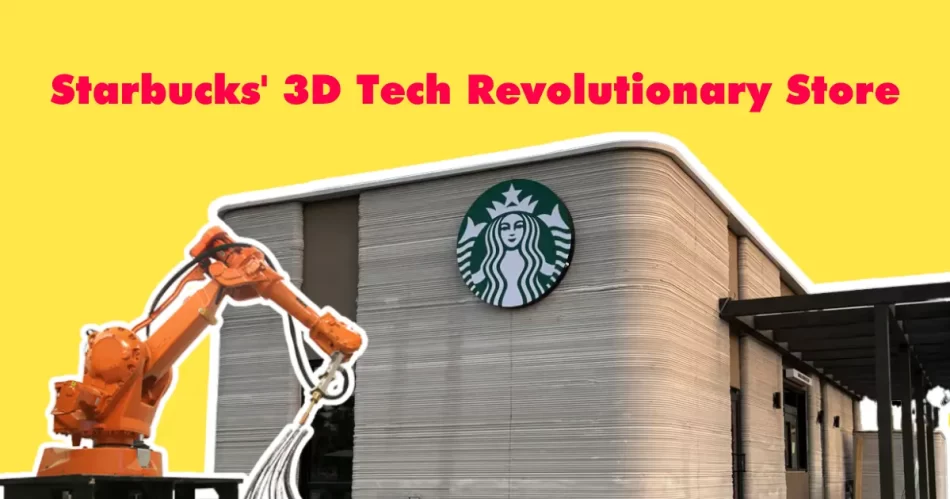

In a move that blends innovation with sustainability, Starbucks has opened its first-ever 3d-printed store in Texas. Constructed using modular and recyclable materials, the 3d printing store represents a major milestone not just for retail design but for the future of manufacturing.

This real-world application of 3D technology brings up an important question:

Will 3d printing make traditional factories a thing of the past?

Let’s explore 3d printing potential and limitations and what this shift means for the future of industrial production.

What Is 3d Printing?

Also known as additive manufacturing, 3d printing is the process of creating three-dimensional objects from digital designs by layering material one step at a time. This technique offers unmatched design freedom, minimal waste, and the ability to create complex shapes that traditional manufacturing cannot easily replicate.

Industries such as healthcare, aerospace, automotive, and now retail are leveraging 3D printing not just for prototyping but for actual end-use parts and structures. The technology is further enhanced when combined with AI-powered design tools, allowing for smarter, faster, and more efficient product development.

What are the Advantages and disadvantages of 3D Printing

As demonstrated by Starbucks’ store, offers several key advantages:

- Design Flexibility: Create complex structures without tooling limitations.

- Faster Prototyping: Accelerates the product development cycle.

- Sustainable Production: Reduces material waste by using only what’s needed.

- On-Demand Manufacturing: Eliminates the need for large inventories.

- Customization at Scale: Products can be tailored to individual customer needs.

These benefits are especially valuable in industries where agility, speed, and sustainability are critical.

The Limitations That Keep Traditional Factories Relevant

Despite its promise, 3d printing is not a complete substitute for conventional manufacturing, at least not yet. Here’s why:

- Scale and Speed: Traditional factories are still faster and more cost-efficient for mass production.

- Material Limitations: Not all materials can be 3D printed, especially for heavy-duty applications.

- Mechanical Properties: Printed parts sometimes lack the strength or durability of traditionally made components.

- Higher Costs for Large Volumes: For large-scale production, additive manufacturing can be slower and more expensive.

These constraints mean that while this tech advancement excels in specialized areas, it doesn’t fully replace factory-scale operations.

A Hybrid Approach: The Future of Manufacturing

Rather than replacing traditional factories, 3D printing complements them. Manufacturers are increasingly adopting a hybrid model, where additive manufacturing is used for:

- Rapid prototyping

- Short-run production

- Custom components

- Complex design parts

Meanwhile, traditional manufacturing handles high-volume, standardized production. The combination of both enables companies to optimize production workflows and respond to changing market needs with greater flexibility.

AI integration further bridges the gap between these technologies, enhancing everything from predictive maintenance to real-time design feedback and process automation.

Real-World Use Cases: Beyond Starbucks

The Starbucks 3D-printed store isn’t an isolated case. Other industries are actively incorporating this trending technology into their core operations.

For instance, Czinger, a Los Angeles-based automotive company, uses 3D printing and AI to produce the 21C hypercar—a lightweight, performance-driven vehicle that reflects the future of smart manufacturing.

This Instagram Reel highlights another real-world application of 3d printing technology to illustrate the growing impact of additive manufacturing further. It demonstrates how industries are adopting innovative approaches to design and production.

From architecture to aerospace, the shift is clear: 3D printing is becoming mainstream.

Conclusion: Will 3D Printing Replace Traditional Factories?

The answer is no, but it will transform them.

3D printing will not make factories obsolete, but it will play a crucial role in reshaping how we design, build, and deliver products. The Starbucks 3D-printed store stands as a powerful example of what’s possible when creativity meets technology.

The future of manufacturing lies in a balanced, hybrid approach—where traditional and additive methods work hand-in-hand to deliver efficiency, sustainability, and personalization at scale.